Best in Class IEC Soft Starter

With built-in full motor overload protection as well

as full data logging, field serviceable fans, upgradable

firmware and extensive input/output programmability,

VMX-synergy™ meets all of the key design criteria.

Easy of Use

The display will show all messages in full and 15 different

global languages. The use of graphic/schematic

images and active mimic diagrams will facilitate complete

understanding. Detailed logging will aid setup

and onboard USB allows configurations to be upload/downloaded

and emailed.

Auto Configuration

The automatic functionality has been expanded so that more

features can be configured without referring

to parameter lists.

Energy Savings

Energy optimizing is combined with bypass to give energy saving

in more applications.

Automatic Load Tuning

The VMX-Synergy™ will ‘tune’ itself to the load.

Touch Screen

The VMX-synergy™ comes standard with a color touch screen on all

sizes.

AC Supply Voltage: 200 - 480 Vac

HP Ratings: 10 to 400 HP

Amp Ratings: 17 to 477 Amps

Application: 42 Profiles.

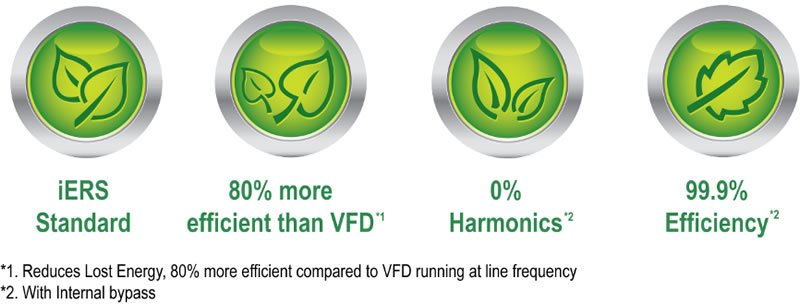

Energy Savings: iERS System

Bypass: Built-in

iERS – intelligent Energy Recovery System

iERS is an advanced motor control technology for use in fixed

speed applications. It is proven to reduce the energy consumed

in a variety of industrial and commercial applications and has

been implemented in every market from HVAC to Oil and Gas. In

the industrial sector it is becoming increasingly important to

offer technology that meets the corporate social

responsibilities of companies as well as reducing the overall

running costs of equipment and minimizing downtime and

maintenance. iERS is a technology that matches the power

consumption to the load required. It intelligently monitors and

regulates energy consumption on fixed speed motors. It also

monitors the voltage, current and power factor during the start

to calculate the full load figures. During the running stage,

the power factor continues to be monitored.

When the power factor drops, the motor is lightly loaded, and

there are losses inherent in the design of a motor causing

excess energy to be wasted. These are known as excitation

losses. iERS’s consistent monitoring automatically recognises

these costly losses, and in turn reduces the voltage and

current, to not only increase the part load power factor, but to

reduce the energy consumption in kW and allow motor to run

cooler. When the power factor increases, the motor is more

loaded. iERS then automatically bypasses itself to remove any

losses within the equipment.

|

Power Components Line Voltage Range Current Ratings Control Voltage Bypass Enclosure Overload Energy Savings |

Input/Outputs Setup Data Logging Touch Screen Languages Communication |

VMX-synergy Brochure 5.56 MB (PDF)

VMX-synergy Brochure 5.56 MB (PDF)  VMX-P Brochure 2.01 MB (PDF)

VMX-P Brochure 2.01 MB (PDF)  VMX-synergy Quick Start Guide 2.28 MB (PDF)

VMX-synergy Quick Start Guide 2.28 MB (PDF)  VMX-synergy User Manual 6.63 MB (PDF)

VMX-synergy User Manual 6.63 MB (PDF)  VMX-synergy Parameter Tables 1.31 MB (PDF)

VMX-synergy Parameter Tables 1.31 MB (PDF)  VMX-synergy Fan Installation Guide 1.22 MB (PDF)

VMX-synergy Fan Installation Guide 1.22 MB (PDF)  VMX-synergy Modbus Parameter Tables 1.33 MB (PDF)

VMX-synergy Modbus Parameter Tables 1.33 MB (PDF)  VMX-synergy Remote Keypad User Guide 748 KB (PDF)

VMX-synergy Remote Keypad User Guide 748 KB (PDF)  VMX-synergy Ethernet IP Module User Guide 908 KB (PDF)

VMX-synergy Ethernet IP Module User Guide 908 KB (PDF)

VMX-synergy Profibus DP Module User Guide 818 KB (PDF)

VMX-synergy Profibus DP Module User Guide 818 KB (PDF)

VMX-synergy Log File Download 1MB (PDF)

VMX-synergy Log File Download 1MB (PDF)  VMX-synergy Firmware V5970 1.48 MB (ZIP)

VMX-synergy Firmware V5970 1.48 MB (ZIP)  VMX-synergy Ethernet IP EDS File 0.99 MB (ZIP)

VMX-synergy Ethernet IP EDS File 0.99 MB (ZIP)  VMX-synergy Profibus GSD File 3 KB (ZIP)

VMX-synergy Profibus GSD File 3 KB (ZIP)  VMX-synergy Simulator PPT 0.99 MB (ZIP)

VMX-synergy Simulator PPT 0.99 MB (ZIP)